|

| |

Motorized Linear Vertical Stage

|

|

Home

>

Motorized Vertical Single-axis Stages

|

The AZ60-A Motorized Vertical Elevator Stage is a low-profile and compact 183.7 mm x 80 mm x 38 to 42-mm (raised) stage.

It

perfectly suited for low cost, high resolution, wedge type, vertical elevator applications requiring precise vertical positioning.

The

60 mm x 87 mm (2.362 in. x 3.425 in.) drilled and tapped stage has a vertical travel of 4 mm (0. 157 in.).

The crossed roller guides and a precision ground 8-mm-diameter 250 microns/turn lead ball screw provides smooth, straight (straightness to better than 5 microns). More after the jump.

The stage delivers good parallelism (<20 microns to the mounting surface), and high resolutions to 1.25 microns (full step), 0.625 microns (1/2 step), and 0.125 microns (1/10 micro step), and repeatability to +/- 0.5 microns. Travel speeds are up to 2.5 mm/sec.

The typical applications for the AZ60-A elevator stage include:

• Photonic alignment, wafer inspection, precision vertical alignment, laser marking

• Optical positioning, testing, inspection, assembly, sampling

• Laser drilling and machining in a broad range of industrial, medical, semiconductor, and research facilities

The AZ60-A Elevator Stage is constructed of black-anodized aluminum alloy and weighs just 1.14 kg (2.51 lb). A powerful NEMA 14 1.8 Deg 2-phase stepper motor has a double ended shaft with a knob for manual adjustments. This knob may be replaced with a quadrature encoder for position verification. The non-cantilevered moving wedge elevator stage has a Load Capacity of 7 kg (15.43 lb) without concern for loss of parallelism, and the base plate has easy to access holes for mounting.

This product has been featured in the following sites,

https://www.automation.com

https://en.ofweek.com

https://www.engineeringspecifier.com

https://www.linearmotiontips.com

|

|

|

Specifications

|

|

Specifications

|

Type

|

AZ60 - A

|

|

M

e

c

h

n

i

c

a

l

s

p

e

c

|

Table Size |

87 X 60 mm |

| Range of Travel |

4 mm

|

| Travel Guide |

Ball screw Φ8, lead 250

micron

/ turn |

| Runway |

Cross-roller lead-type |

|

Load

|

7 Kg |

|

Body Weight

|

1.14 Kg |

|

Material

|

Aluminum Alloy |

|

Surface treatment

|

Black Anodized |

|

T

y

p

i

c

a

l

P

r

e

c

i

s

i

o

n

S

p

e

c

|

2-phase

resolution

(pulse) |

Resolution |

1.25

micron / 0.625

micron

|

| Micro Stepping(1/10 step) |

0.12

5

micron

|

|

Parallelism

|

20

micron

|

|

Maximum Speed

|

2.5 mm / sec

|

|

Positioning Precision

|

5

micron

|

|

Repeatability

|

+/- 0.5

micron

|

|

Parallelism

|

30

micron

|

|

Dynamic Straightness

|

5

micron

|

|

Dynamic Parallelism

|

20

micron

|

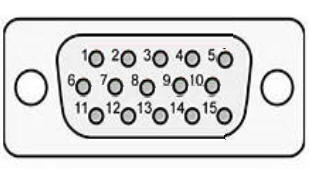

Electrical Connection

|

Pin No.

|

Description

|

| Two-Phase Stepper Motor (1.8 Deg) |

35H36H-1004B |

| Typical Phase Resistance |

2.7 Ohms, Bi-directional |

| Typical Phase Current |

1 Amp |

DB-15

Male Connector

|

Pin No.

|

Description

|

| 1 |

Stepper Motor Stepper Motor Phase A+ |

| 2 |

Stepper Motor Stepper Motor Phase A- |

| 3 |

Stepper Motor Stepper Motor Phase B+

|

| 4 |

Stepper Motor Stepper Motor Phase B- |

| 5 |

Not Connected

|

| 6 |

Not Connected

|

| 7 |

Not Connected

|

| 8 |

Not Connected |

| 9 |

+5 VDC Power Input

|

| 10 |

One Pulse per Motor Revolution, Open Collector. Normally High, Active Low

|

| 11 |

+5 VDC Power Input Common

|

| 12 |

Not Connected

|

| 13 |

Not Connected |

| 14 |

Not Connected |

| 15 |

Not Connected |

|

|

|

Stepper Motor Driven Mechanical Drawing

|

|

|

|

|

Ordering Information

|

Part No.

|

Description

|

Amount

|

|

AZ60-A

|

Stepper Motor Driven

Linear Vertical Stage, Table Size

87 x 60 mm

|

Click to Get a Quote

|

|

|