|

| |

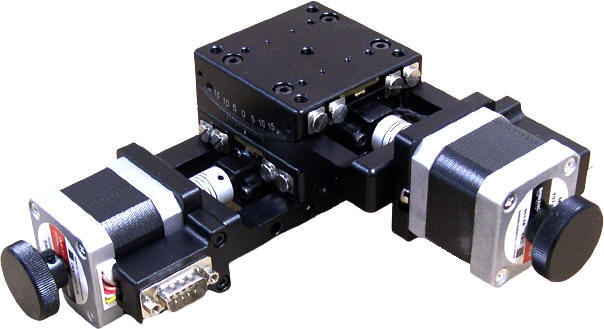

Dual-axis Pitch and Roll Stage

|

|

Home

>

Motorized Yaw, Pitch and Roll Stages

|

|

|

|

|

The

Dual-axis Pitch and Roll Stage

are used for: Identifying crystals, examining cutting edges of medical instruments, estimating hyperspectral bidirectional reflectance, gloss measurements, measurements of radiation patterns of LEDs, Directing lasers, aligning mirrors, and manufacturing of quartz oscillator plates using quartz cutting x-rays.

The lower stage features

+/-

15

Degrees of rotation at a rate of 14

Degrees

per second with stepper motor and 90 Degrees per second with Three Phase Brushless Servo Motor with Quadrature Incremental Optical Encoder. The upper stage features a 65 mm x 65 mm table,

+/-

15 Degrees of rotation at a rate of

14

Degrees per second with stepper motor and 90 Degrees per second with Three Phase Brushless Servo Motor with Quadrature Incremental Optical Encoder. The accuracies for each unit are; repeatability:

+/- 4" (240 arcseconds), typical Positioning accuracy: +/- 9" (540 arcseconds).

The precision, compact Dual-axis Pitch and Roll Stage

stage, available with either stepper, Three Phase Brushless Servo Motor with Quadrature Incremental Optical Encoders, optical encoders or manual adjustment knobs. It has a footprint of just 169 mm x 169 mm, and can be supplied plug-and-play with a motion controller. It is easily integrated into an inspection, testing, or manufacturing environment.

The Dual-axis Pitch and Roll Stages require a

Motion Controller

that can be ordered as a complete plug-and-play system with RS-232, USB, joystick and keypad control.

|

|

|

|

Specifications

|

Type

|

PR110-15-15

|

|

Range of Travel |

+/-15 Deg (Roll Axis)

+/-15 Deg

(Pitch Axis )

|

|

Table Size |

65 mm x 65 mm

|

|

Gear Ratio |

1 Deg (stage) :

252 Deg (motor) (Roll Axis)

1 Deg (stage) : 252 Deg (motor) (Pitch Axis)

|

|

Drive Mechanism |

Worm Gear |

|

Travel Guide

|

Crossed-roller Guide |

|

Stepper Motor

|

|

|

|

Typical Phase Resistance

|

3.8 Ohms, Bi-directional

|

| Typical Phase Current |

1 Amp |

|

DB-9 Male Connector

|

|

Pin Assignment and Description

|

|

1

|

+5 VDC

|

|

2

|

CCW Limit Switch

, Open Collector, Normally Open, Needs Pull up Resistor

|

|

3

|

CW Limit Switch, Open Collector

, Normally Open, Needs Pull up Resistor

|

|

4

|

Common

|

|

5

|

Not Connected

|

|

6

|

Stepper Motor Phase A+

|

|

7

|

Stepper Motor Phase A-

|

|

8

|

Stepper Motor Phase B+

|

|

9

|

Stepper Motor Phase B-

|

|

|

|

Base Material

|

Aluminum Alloy |

|

Surface Treatment

|

Black Anodized |

|

Load Capacity |

4.5

kg

|

|

Weight

|

1.5 kg

|

|

Height of Rotation |

50 mm |

|

Maximum Speed |

14 Deg/sec |

|

Typical Repeatability |

+/-4‘ |

|

Typical Positional Accuracy |

+/-9‘ |

|

Typical Backlash |

+/-3‘ |

|

|

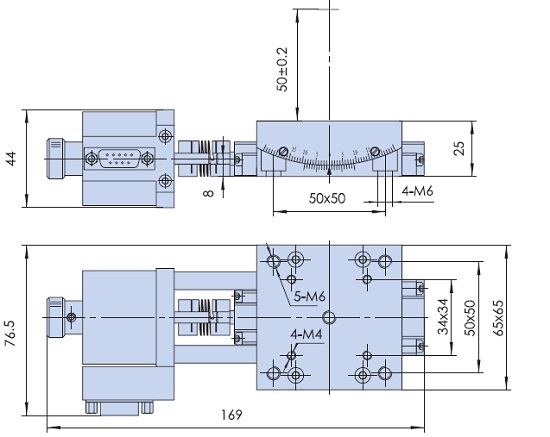

Stepper Motor Driven Mechanical Drawing (Roll Table)

|

|

Ordering Information

|

Part No.

|

Description

|

Amount

|

|

PR

110-15-15-01

|

Dual-axis Stepper Motor Driven Linear Pitch and Roll Stage, Table Size

65x65 mm

|

Click to Get a Quote

|

|

PR

110-15-15-02

|

Dual-axis

Three Phase Brushless Servo Motor with Quadrature Incremental Optical Encoder Driven Pitch and Roll Stage,

Table Size

65x65 mm

|

Click to Get a Quote

|

|

PR

110-15-15-03

|

Dual-axis DC Servo Motor with Quadrature Incremental Optical Encoder Driven Pitch and Roll Stage,

Table Size

65x65 mm

|

Click to Get a Quote

|

|

PR

110-15-15-04

|

Dual-axis Stepper Motor Driven Linear Pitch and Roll Stage

with 500 Cycles per Revolution Quadrature Optical Encoders

Mounted at the back of the Stepper Motors

, Table Size

65x65 mm

|

Click to Get a Quote

|

Related Products

|