|

| |

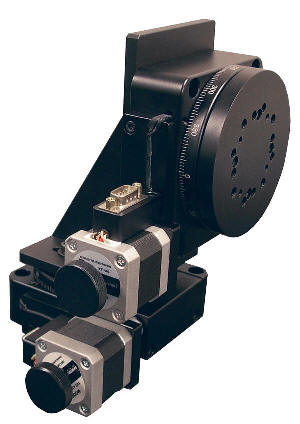

Motorized Two-axis

Pan-Tilt Stage, 100 mm Diameter

|

Home

>

Assorted Motorized Pan-Tilt Actuators

|

|

Stepper Motor

Driven Two-axis Pan-Tilt Stage

|

|

|

|

DC

Motor

Driven Two-axis Pan-Tilt Stage

|

Stepper Motor

Driven Two-axis Pan-Tilt Stage with Optical Encoders

|

|

|

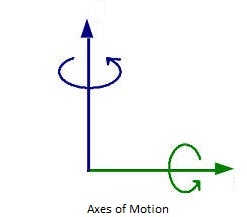

The PT100 Pan-Tilt Stage is a combination of two 100 mm (3.937 in.) rotary stages set at a 90 Degrees angle to each other. The rotary stages of each Pan-Tilt stage features a high repeatability of 0.005 Degrees (18 arc-sec), a positional accuracy of 0.005 Degrees (18 arc-sec), and a resolution of 0.001 Degrees (3.6 arc-sec) when 10 Micro-steps per Step Motor Driver is in use. These Pan (horizontal table)-Tilt (vertical table) stages are deal for: Scanning, testing, inspection, assembly, positioning, laser and micro machining, pointing optics and cameras, and other applications.

The pan and tilt axes on both stages have precision V-grove and crossed roller travel guides and are driven by a worm gear with just of 0.005 Degrees (18 arc-sec) of backlash.

Each axis is driven by a standard bi-directional stepper motor with a knob for manual adjustments and each rotary axis has a vernier scale for setup. The knob on each motor can be replaced with an optical encoder for position verification. Travel speed of each axis is 12 Degrees per second with the stepper motors For higher speeds and closed loop operation, servo motors are also available. Electrical connections are made using 9 pin DB-9 connectors.

The PT100 Pan-Tilt Stage can be ordered as complete plug-and-play systems with a

Motion Controllers

,

joystick or keypad control.

Video Demonstration |

|

Specifications

|

Type

|

PT100

|

|

Structure

Description

|

Range of Travel |

360 Deg

Continuous

on Tilt Axis |

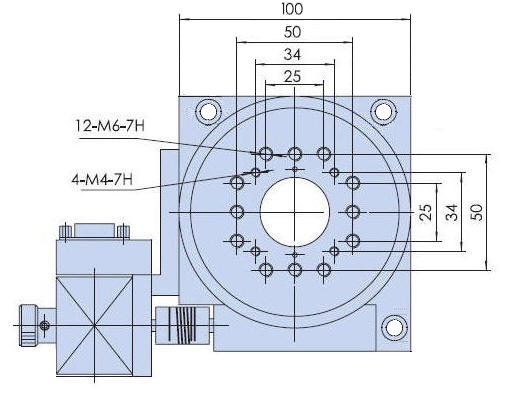

| Table Size |

Diameter: 100 mm (3.937 in)

|

| Gear Ratio |

180:1 |

| Actuator Type |

Worm and Worm Gear |

| Travel Guide |

Precision V-groove & Crossed Roller |

|

Pan

and Tilt

Motors

|

| Typical Phase Resistance |

3.8 Ohms, Bi-directional |

| Typical Phase Current |

1 Amp |

|

DB-9 Male Connector

|

|

Pin Assignment and Description

|

| 1 |

+5 VDC for the HOME Sensor |

| 2 |

Not Connected

|

| 3 |

Not Connected

|

| 4 |

Return for+5 VDC

|

|

5

|

Home Switch

Open Collector

Normally Open

Needs Pull up Resistor (typically 1000 Ohms)

|

|

6

|

Stepper Motor Phase A+ |

| 7 |

Stepper Motor Phase A- |

| 8 |

Stepper Motor Phase B+ |

| 9 |

Stepper Motor Phase B- |

|

| Base Material |

Aluminum Alloy |

| Surface Treatment |

Black Anodized |

| Load Capacity |

20 kg |

| Weight with Stepper Motors |

4.4 kg (9.75 lb) |

|

Weight with DC Motors

|

5.2 kg (11.5 lb)

|

Resolution |

0.001 Deg = 3.6 arc-sec (10 Micro-steps per Step Motor Driver in use)

|

|

Maximum Speed of the Pan axis with Stepper Motor

|

12 Deg/sec |

|

Maximum Speed of the Tilt Axis with Stepper Motor

|

12 Deg/sec |

|

Maximum Speed of the Pan Axis with Servo Motor

|

90

Deg/sec |

|

Maximum Speed of the Tilt Axis with Servo Motor

|

90

Deg/sec |

|

Typical Accuracy

|

|

Positional Accuracy

|

0.05 Deg = 180 arc-sec |

|

Repeatability

|

+/- 0.01 Deg = +/- 36 arc-sec |

|

|

|

Tilt-axis Stepper Motor Driven Mechanical Drawing

|

Ordering Information

|

Part No.

|

Description

|

Amount

|

|

PT100-01

|

Stepper Motor

Driven Two-axis Pan-Tilt

Stage, 100 mm diameter

|

Click to Get a Quote

|

|

PT100-02

|

Three Phase Brushless

Servo

Motor

with Quadrature Incremental

Optical Encoder

Driven

Two-axis Pan-Tilt

Stage, 100 mm diameter

|

Click to Get a Quote

|

|

PT100-03

|

DC Brush

Servo

Motor

with Quadrature Incremental

Optical Encoder

Driven

Two-axis Pan-Tilt

Stage, 100 mm diameter

|

Click to Get a Quote

|

|

PT100-04

|

Stepper Motor

Driven Two-axis Pan-Tilt

Stage

with 500 Cycle per

Revolution

Quadrature Optical Encoder

Mounted on the Back of the

Stepper Motors

, 100 mm diameter

|

Click to Get a Quote

|

|

|

|

Related Products

|